- Solution

- Aerospace 3C Digital Automotive sector Grinding tool gear Hardware machinery 3D Printing Medical devices

HengliHong ceramic sand is a process in which the projectile flow continuously impacts the surface material of fasteners, causing cyclic plastic deformation of the surface material. The surface layer that undergoes cyclic plastic deformation will undergo one or several changes depending on the type of ceramic bead:

1. Formation of residual compressive stress field within the surface layer;

2. The variation of substructure (subgrain) size and lattice distortion of surface materials;

3. Plastic induced phase transition of ceramic beads;

4. The change in material density within the plastic deformation layer of ceramic beads.

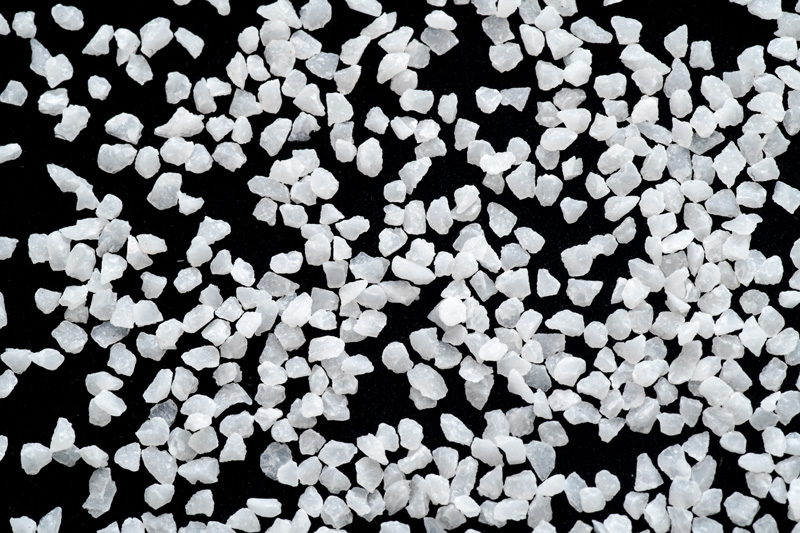

Ceramic sand undergoes cyclic plastic deformation and introduces a residual compressive stress field on the surface of the material, which is superimposed on the tensile stress of the applied alternating stress in the same section, causing the large tensile stress borne by the material to move from the surface to the sub surface position. The fatigue crack of the surface unreinforced specimen originates from the outer surface, while the fatigue crack of the surface deformation strengthened specimen originates from the subsurface layer. Theoretical analysis confirms that residual stress caused by deformation can lead to the initiation of fatigue cracks on the subsurface of the material, resulting in an internal fatigue limit 1.05-1.35 times higher than the surface fatigue limit. Surface strengthening is an effective surface strengthening process for improving the stress corrosion and hydrogen embrittlement fracture resistance of fasteners. The pellets include cast steel pellets, glass pellets, ceramic pellets, etc. The surface roughness of the strengthened fastener is 0.65 μ M-2 μ m. Reachable surface roughness of 0.63-2.5 μ m. The reliability and durability of the workpiece can be significantly improved and enhanced. Ceramic beads are a characteristic abrasive widely used in cleaning or metal surface strengthening processes, mainly used in sandblasting equipment. Ceramic sand is made by crushing and sorting high-quality broken glass. In manufacturing, broken glass needs to be melted into spherical shapes and then annealed to eliminate internal stress and prevent damage. This transparent and clear spherical structure product will not have particles embedded in the workpiece, contaminate the workpiece, or cause other damage during use. Using different sizes of abrasives and operating parameters, ceramic sand can achieve different glossiness on the surface of the workpiece. Choosing ceramic sand for selective local coverage controlled sandblasting on the surface of the workpiece can produce a special decorative effect.