- Solution

- Aerospace 3C Digital Automotive sector Grinding tool gear Hardware machinery 3D Printing Medical devices

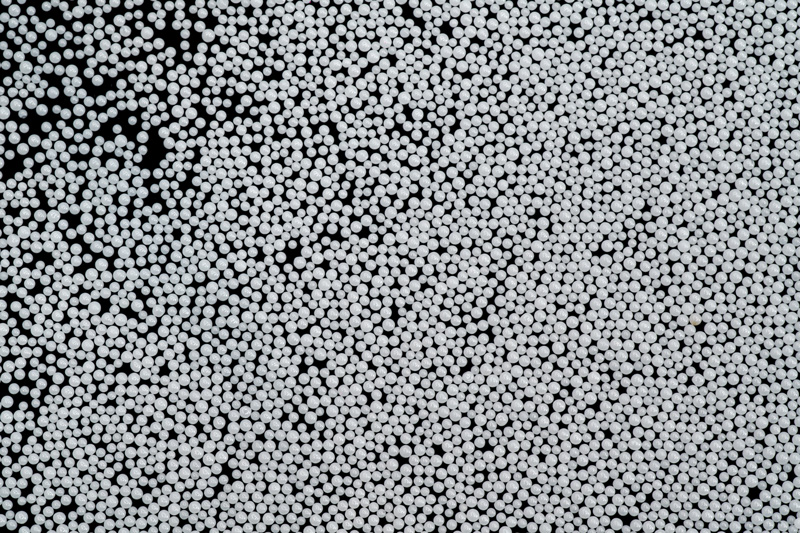

B microsphere sandblasting and shot peening ceramic beads, suitable for sandblasting and shot peening surface treatment. Materials include: stainless steel, aluminum alloy, titanium alloy, plastic workpieces, etc. Surface sandblasting and shot peening strengthening can improve the service life of workpieces, which are not fragile and environmentally friendly and pollution-free.

Microspheres (white) Series B

The microstructure is very small Zro2 (usually 1-2um in diameter) with a tile like distribution of SiO on the matrix, thus possessing excellent wear and impact resistance. On the other hand, it also ensures its strength and hardness, making ceramic sand have good wear resistance and impact resistance. The coarse organizational structure not only reduces the strength and hardness of the projectile, but also reduces its toughness, which will lead to premature fracture and fragmentation of the projectile during use. The microstructure is very small Zro2 (usually 1-2um in diameter) with a tile like distribution of SiO on the matrix, thus possessing excellent wear and impact resistance. On the other hand, it also ensures its strength and hardness, making ceramic sand have good wear resistance and impact resistance. The coarse organizational structure not only reduces the strength and hardness of the projectile, but also reduces its toughness, which will lead to premature fracture and fragmentation of the projectile during use.

Technology:

The raw materials are fired by the electric melting method, and its unique internal crystal structure ensures its strong hardness and impact resistance. The spherical shape, smooth surface, and dust-free characteristics provide prerequisites for a good working environment. The stable chemical inertness ensures that the processed workpiece will not be contaminated.

| ZrO2 | SiO2 | Al2O3 | Density | Bulk density | Hardness reference value | ||

| 60-70% | 28-33% | <10% | 3.8 | 2.2 | 700(HV) | 7(F. Mons) | (60HRC) |

For you to choose from:

You can control the surface roughness Ra value, surface glossiness L value, Rz value, RP value, RQ value, RSM value, A value, etc. through size. Whether your material is copper, stainless steel, or plastic parts, we have a good surface treatment plan to meet your needs. At the same time, we also provide one-on-one metal surface treatment sandblasting; Senior professional shot peening engineers provide online technical support to serve you!

| B | B | B | |||

| HLH-B20 | 0.600-0.850mm | HLH-B80 | 0.180-0.250mm | HLH-B150 | On demand |

| HLH-B30 | 0.425-0.600mm | HLH-B100 | 0.125-0.180mm | HLH-B180 | On demand |

| HLH-B40 | 0.250-0.425mm | HLH-B170 | 0.045-0.090mm | HLH-B220 | On demand |

| HLH-B60 | 0.125-0.250mm | HLH-B505 | 0.010-0.030mm | HLH-B280 | On demand |

| HLH-B120 | 0.063-0.125mm | / | / | HLH-B320 | On demand |

| HLH-B125 | 0.000-0.125mm | / | / | HLH-B400 | On demand |

| HLH-B205 | 0.000-0.063mm | / | / | HLH-B450 | On demand |

| * HLH® Customizable according to your requirements* | |||||